Description

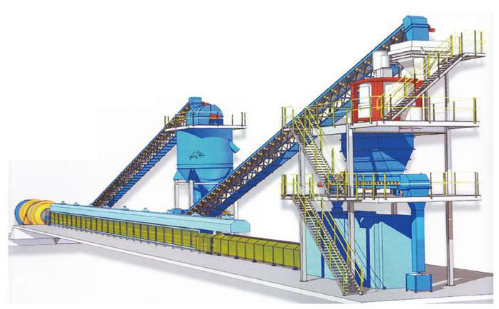

Water heating fittings casting line manufacturing process

Sand treatment process — moulding making — casting — cleaning

D417B The vertical moulding machine is a casting equipment used for making sand moulds. Its main function is:filling sand ,Fill the loose molding sand into the sand box; Compacted sand, The loose sand in the sand box is compacted by different methods, such as compaction, compaction, shock compaction and injection compaction ,:Make the sand mold have the necessary strength in the process of handling and pouring; take -out mold shape , using different mechanisms to take out the shape from the compacted sand mold;Hydraulic pressure is used as the driving force for sand compaction.

D417B The vertical molding machine has realized the mechanical automation to replace the manual work, It integrates the functions of automatic feeding, sand grinding, dust removal, auxiliary material recovery, product sorting, processing and re-concentration,Overall technological structure design and layout use advanced science,Widely used in automobiles, compressors, water heating pipe fittings, malleable steel parts ;High degree of automation, greatly saving manpower,Solve casting labor difficulties(Employment in traditional operations is now more than three times that of existing automation);high production capacity, is more than 6 times the efficiency of traditional operation;Automatic constant temperature pouring is designed,Unified casting process to ensure the quality of products;Non-standard parts design and production reasonable and perfect,No air leakage phenomenon, no dust emission, protect the workshop site working environment and operators safety.